Product Description

ZheJiang CHINAMFG PLASTIC MOULD CO.,LTD, located in ZheJiang China. we make product design, injection mould design and manufacture, injection production, printing, ultra- welding & welding, and product assembly, and high-cycle blowing package in one.

With a total investment of RMB 5 millions, ZheJiang CHINAMFG PLASTIC MOULD CO.,LTD. has a modern factory with building area of more than 2000 square meters, with advanced equipments. And there are 3 experienced designers, 15 skilled mould makers and injection machines operators.

Our clients throught the world, especially from the United states, Sweden, Italy, Mexico,France, Spain, Norway, Kuwait, Japan, India, Srilanka and so on. Our main produts are plastic injection moulds and injection moulding, products cover medical apparatus and instruments, automobile products, motorcycle accessories, electric tool, GYM equipments,electronic devices,office equipment and writing insruments and so on. We make products for INTEL, HP, KUM and others, and keep good business partnership with ZHangZhouG UNIVERSITY, ZheJiang UNIVERSITY and other colleges and universities.

Nowdays, we have senior designers and skilled mould makers more than 50, 10 professional managers and QC inspection persons. Furthure more, we adopt advanced international design software and system, combine modern quality control system, deeply through contract review, design and development, material purchasing, manufacturing, trial and testing,injection production and after-sales service.

Our consistent purpose is to supply high-quality products, excellent service with reasonable price to our clients overseas.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

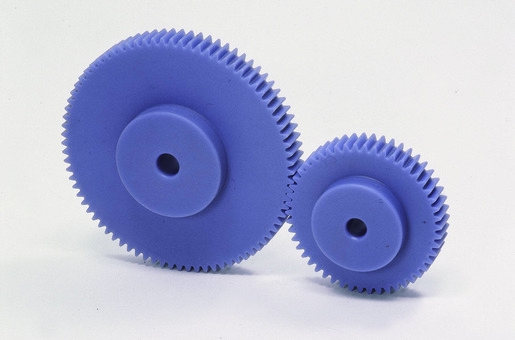

| Material: | ABS |

|---|---|

| Color: | Customized |

| Transport Package: | Fumigation Carton |

| Specification: | customized |

| Trademark: | jesun mould |

| Origin: | Shanghai, China |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

What are the factors affecting the durability of plastic gears?

The durability of plastic gears can be influenced by various factors. Here’s a detailed explanation of these factors:

1. Material Selection: The choice of plastic material is a critical factor affecting the durability of plastic gears. Different plastic materials have varying mechanical properties, including strength, stiffness, impact resistance, and wear resistance. Selecting a material with suitable properties for the specific application is essential to ensure long-term durability.

2. Load and Stress: The magnitude and distribution of the applied load significantly impact the durability of plastic gears. Excessive loads or high stress concentrations can lead to deformation, fatigue, or even failure of the gear teeth. Proper consideration of the anticipated loads and stress distribution is crucial during the design phase to ensure that the gears can withstand the expected operating conditions.

3. Operating Speed: The rotational speed at which the plastic gears operate can affect their durability. Higher speeds can generate more heat due to friction, potentially leading to thermal degradation or wear. The material selection and design should account for the anticipated operating speeds to ensure that the gears can withstand the associated stresses and temperature rise without compromising their durability.

4. Lubrication: Proper lubrication is vital for reducing friction, minimizing wear, and enhancing the durability of plastic gears. Insufficient or improper lubrication can result in increased friction, leading to accelerated wear and potential gear failure. The selection of suitable lubricants and appropriate lubrication methods is essential to ensure optimal performance and durability.

5. Environmental Conditions: The environmental conditions in which plastic gears operate can impact their durability. Factors such as temperature extremes, humidity, exposure to chemicals or UV radiation, and presence of abrasive particles can degrade the plastic material over time. It’s important to consider the anticipated environmental conditions and select a plastic material that offers sufficient resistance to these factors.

6. Gear Design: The design of plastic gears can greatly influence their durability. Factors such as tooth profile, gear geometry, clearances, and load distribution should be optimized to minimize stress concentrations, prevent excessive wear, and ensure even load distribution across the gear teeth. Proper design considerations, including appropriate fillets, reinforcements, and tooth profiles, can improve the durability of plastic gears.

7. Manufacturing Quality: The quality of the manufacturing process and the precision of the gear manufacturing can impact its durability. Inadequate manufacturing processes or poor quality control can result in dimensional inaccuracies, surface defects, or material inconsistencies that can compromise the gear’s durability. Ensuring high-quality manufacturing practices and inspections is essential to maintain the durability of plastic gears.

8. Maintenance and Service Life: The maintenance practices and service life of plastic gears can affect their durability. Regular inspection, proper lubrication, and timely replacement of worn or damaged gears can help extend their lifespan. Neglecting maintenance or operating gears beyond their intended service life can lead to accelerated wear and reduced durability.

By considering these factors, such as material selection, load and stress, operating speed, lubrication, environmental conditions, gear design, manufacturing quality, and maintenance practices, it’s possible to optimize the durability of plastic gears and ensure their long-term performance.

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by CX 2024-04-08